CMAC National Facility

The EPSRC Centre for Innovative Manufacturing in Continuous Manufacturing and Crystallisation has Facilities Distributed across 7 Collaborating Universities. The Centre therefore has access to unique, multi-disciplinary capabilities over the broad spectrum areas defined within the scope.

The Strathclyde Technology and Innovation Building (TIC)CMAC has moved into purpose built laboratory and office space in the new TIC building at the University of Strathclyde. This new building co-locates the multi-disciplinary teams of PhDs, Research Associates and academics from across the Centre's projects. The Management Team are located in TIC alongside the researchers. We also have the capability to host research secondments to accelerate delivery on our research. |

|

The EPSRC Centre has moved into a dedicated purpose built laboratory facility for Continuous Manufacturing & Crystallisation Research for Pharmaceutical Products within TIC which will be officially opened during 2015. The facility is equipped using £11.4m funding awarded by the Higher Education Funding Council for England (HEFCE)'s UK research Partnership Investment Fund (UKRPIF) and supported with £22.8m industry and charity contributions. The National Facility will establish world class capabilities in:

- Primary Processing

- Secondary Processing

- PAT/Spectroscopy

- X-Ray Diffraction

- Surface Analysis

- Materials characterisation

Download a copy of the CMAC National Facility flyer here .

Equipment in the CMAC National Facility is searchable and bookable via Ulab.

National Facility Equipment

|

|

|

Primary Processing: CMAC has purchased the Rattlesnake crystallizer from Cambridge Reactor Design. A custom built DN10 is mounted into a frame within a walk-in fumehood in TIC. Radley’s stirred tank reactors (STR)’s have to come to support the growth in projects requiring feed and seed tanks, as well as more advanced platforms including a mixed-suspension mixed-product removal (MSMPR), and even linked to a Dolomite droplet generator. CMAC also purchased new Crystalline and Crystal16 platforms from Technobis, formerly Avantium, to alleviate the high demand for these instruments amongst CMAC researchers. |

|

|

Secondary Processing: A large portion of the RPIF award was targeted on equipment for secondary processing. We have refurbished a lab in TIC specifically to accomodate this equipment. This includes dedicated services and room partitioning to handle dust management. Other items include, a mini-injection molder from ThermoFisher, a conical /hammer mill, Nutsche Filters from PowderSystems. |

|

|

PAT/Spectroscopy: Our current tool kit of PAT probes now includes Bruker Matrix-F for near-IR and Matrix-MF for mid-IR; Bruker’s MultiPurpose Analyser (MPA) for off-line IR analysis; Turbidity probes from HEL. Additionally, pH probes and conductance probes are being rolled out on various platforms. CMAC Tier 2 partner Mettler Toledo, conducted a demonstration of the new V19 PVM probe. |

|

|

Surface analysis: The eagerly awaited TOF-SIMS (Time-of-flight secondary-ion-molecular-spectroscopy) instrument has been delivered by manufacturer ION-TOF in Germany. Related surface analysis techniques include atomic force microscopy (AFM) and surface contact angle goniometer. Other recent additions to this area include simple stereo microscopes, a manual compound microscope for use with Linkam stages, high-end automated inverted and compound microscopes. Also housed within the facility is a Bruker Hyperion 3000 IR microscope, with an attenuated total reflectance (ATR) detector, a grazing angle objective (GAO), and a focal plane array (FPA) detector. Horiba’s XploRA Plus enhances our capability in confocal Raman microscopy. Our new benchtop field emission scanning electron microscope (FE-SEM) from Keysight Technologies opens up new imaging capabilities and eliminates most of the artefacts usually encountered with organic samples on regular high voltage SEM’s.

|

|

|

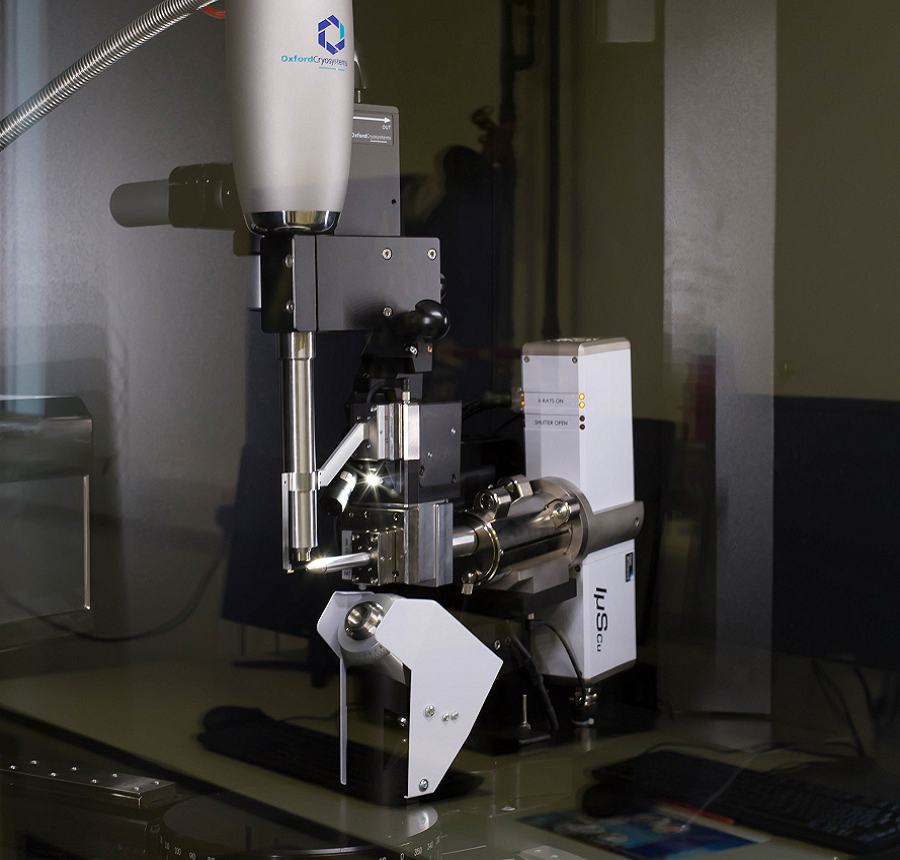

X-Ray Diffraction: We have a dedicated X-ray suite housing 3 Bruker D8 Advance XRPDs, a D8 Venture single crystal which has the D2 Phaser for benchtop powder XRD analysis, new Bruker powder XRD, PANalytical, and X-ray Nano-CT. CMAC, together will colleagues from BioNano and Physics, were successful in a recent EPSRC equipment award which funded a Small Angle X-ray Scattering (SAXS) instrument. |

|

|

Materials Characterisation: State-of-the-art characterisation tools have arrived to enable us to investigate materials from every angle imaginable. Most recent instruments that have been installed include: Netzsch’s Jupiter F1 Simultaneous Thermal Analysis (TGA and DSC) and Polyma 214 Differential Scanning Colorimetry, the FT4 Powder Rheometer from PowderTechnology; the newly released Hydrosight attachment for our Mastersizer 3000 from Malvern; Sympatec’s QicPic/R06; dissolution testing apparatus for USP protocols 1, 2, 4, 5 and 6; a polarimeter; a high speed camera and a thermal imaging camera. |

|

For any enquiries relating to the use of the facility please contact Claire MacDonald, Business Development Manager, on 0141 444 7102 or email national-facility@cmac.ac.uk