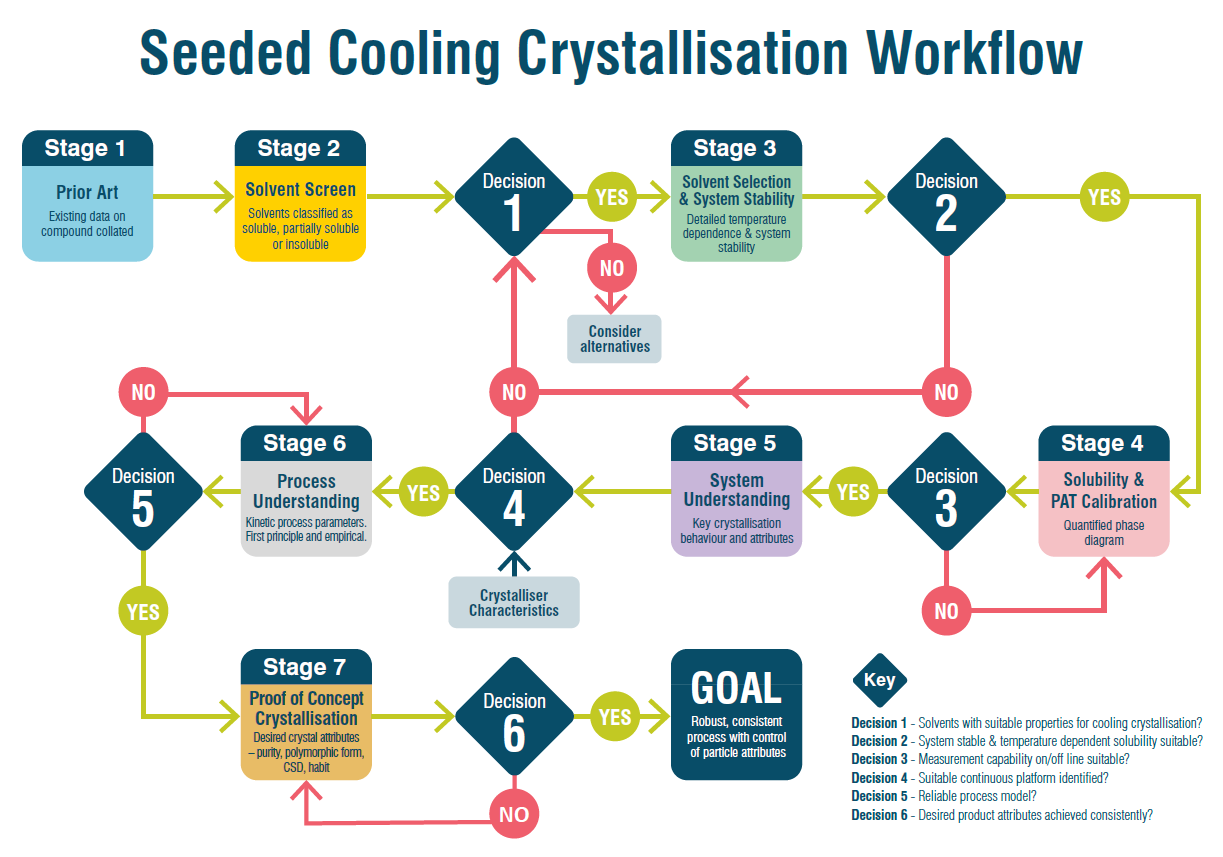

Considerable time has been spent as part of the EPSRC CMAC CIM research campaign, designing and implementing a workflow for continuous cooling crystallisation. Below is the current (at November 2016) version of the workflow for cooling crystallisation with the following qualifying statements:

The workflow is broken into 7 high level stages, each with a clear objective and criteria which inform progression to the next. If critical criteria are not met, the stage is re-visited after which a decision is be made on feasibility of development of a cooling crystallisation process. These data driven decision points will ensure that optimal conditions are used and that specific processes are directed towards the most suitable platforms.

This stage fully characterises and reviews known information on the API under consideration. This informs the rest of the workflow and provides a benchmark to monitor the purity and form of the API during the process.

Image: Analysis of starting material is part of Stage 1

Figure: Typical output from the solvent screening stage

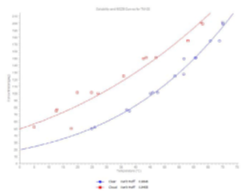

Of the reduced number of solvents carried forward from Stage 2, a more detailed investigation of the temperature dependent solubility is performed using the Crystalline platform. Exposing multiple known concentrations to a heating and cooling cycle allows an approximate phase diagram to be produced. In-situ imaging also allows valuable visualisation. As with the previous stage a design space was determined which considers the potential operating temperature range, yield of solute, final solid mass fraction, metastable zone width, form and chemical stability. These are in addition to qualitative observations relating to agglomeration and fouling. From solvents which fall within this design space a single solvent is selected for the following stages.

Figure: A specific, ramped heating profile is used to determine accurate temperature dependent solubility diagrams

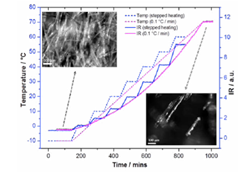

The process conditions for a desired crystallisation are investigated with the primary objective being platform selection. A series of studies are performed to investigate the relative magnitudes of the crystallisation’s: primary nucleation, secondary nucleation, growth rate (measured both as single crystal and in bulk), agglomeration and fouling. Automated evaluation platforms including the Optimax, Crystalline and MF-OBC are used to determine these system parameters.

Figure: Examples of platforms used in Stage 5 a) Optimax, MB-OBC and fouling cell

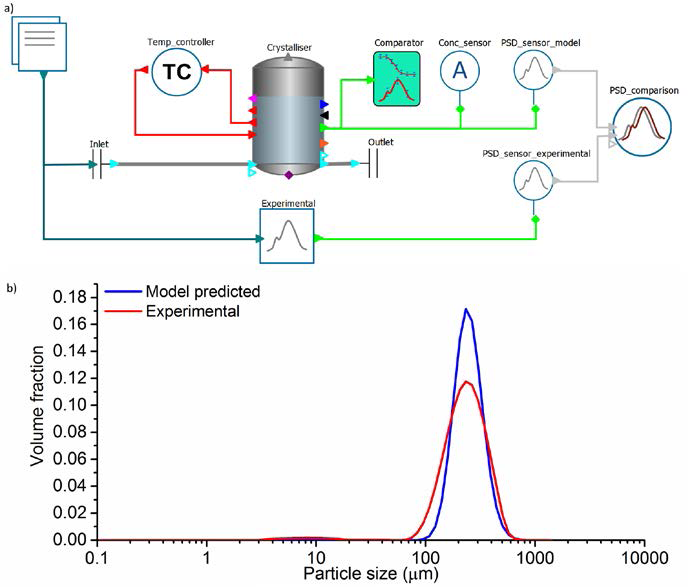

Figure: a) Model flow diagram and b) comparison of model predicted and experimental particle size distribution

While it is entirely feasible to proceed from Stage 5 to Stage 7 using data driven model predictive control approaches which have been developed in partnership with Perceptive Engineering for the processing platforms, we have adopted a hybrid approach where parameter estimation for population balance modelling is used. Parameters for nucleation, growth, agglomeration and breakage, based on experimental results from a DOE approach, are used to assess process conditions (cooling rate, concentration, seed loading) via gCRYSTAL and Matlab.

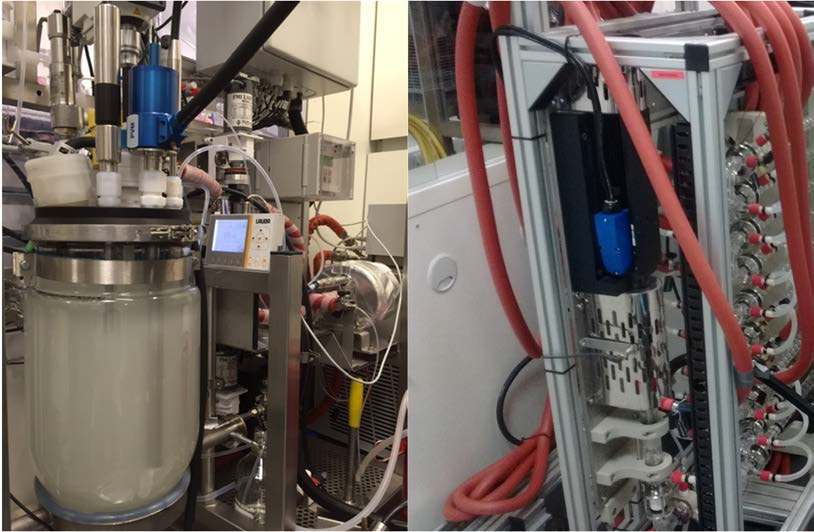

Image: Modular skid mounted crystallisers utilised in Stage 7