CMAC is a key theme within the NPL Scotland Regional Hub, a partnership between the National Physical Laboratory (NPL) and the University of Strathclyde. The partners have successfully developed a joint Doctoral Training Programme with underpinning investment in the key research themes. Initially three joint CMAC-NPL PhD studentships started in October 2015 with researchers splitting their time between the CMAC National Facility at Strathclyde and NPL laboratories in Teddington. Students receive state of the art training in measurement science applied to a range of scientific disciplines and industrial challenges.

Research projects in Metrology for Pharmaceutical Manufacturing, Measurement of Surfaces and Big Data Management are being explored by PhD researchers in the PIMMS collaboration as part of the NPL Scottish Hub at University of Strathclyde.

Laboratories in industry and academia produce extraordinary amounts of files and data that require rigorous research and time costly analysis. For some analytical techniques such as in-line probes used for real time analysis of processes, direct manual analysis of the data is near impossible and automated methods are put in place to control these systems. This project will utilise newly developed and largely successful sections of the open source Berkeley Data Analytics Stack in an attempt to develop an easily scalable system to manage, store, search and analyse large data sets in real time. With particular focus on the fusion of different analytical data sets, the vision is to apply machine learning approaches to enable the analysis of said “big” data sets and visualise them in a comprehensible and meaningful way. Currently the back-bone of the analytical framework has been set up and progress is made towards the analytical platform selected to be incorporated as an introductory-concept.

The aim of this project is to study, define and understand structure-property relationships in continuous pharmaceutical manufacturing processes and products, in order to forecast and control the final product performance. ToF-SIMS and 3D nano SIMS techniques will be applied to the problem. The spectroscopic identification of active ingredient, excipients, impurities and degradation products will also be used to explore the effect of processing and storage on particles’ disposition in complex mixtures at the micron and submicron scale.

Image: ToF-SIMS housed in the Wolfson Pharmaceutical Surfaces Laboratory

Image: ToF-SIMS housed in the Wolfson Pharmaceutical Surfaces Laboratory Figure: Crissy by Zinsser

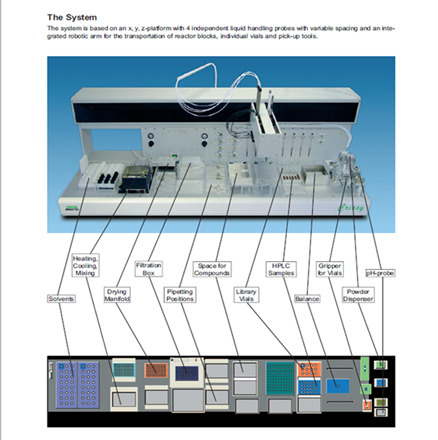

Figure: Crissy by ZinsserThis project aims to deliver new insight into the interaction between surfaces, process operating conditions and solutes for the purpose of delivering unparalleled control over the nucleation process. Crystallisation will be assessed from the vapour phase and from solution and the surface templates that will be studied in the first instance are metal substrates. The model compounds of interest will be the anti-convulsive drug carbamazepine and its structural analogues. Crystallisation from vapour will be investigated through series of sublimation experiments. For the assessment of solution crystallisation, polymorph screening studies will be conducted using Crissy by Zinsser Analytic, a highly automated liquid and powder handling platform that enables the screening of a broad range of solvents and automates the crystallisation process using different solvents, concentrations, temperature gradients, agitation, and pH.