CMAC worked closely with our industry partners with a shared vision to accelerate the adoption of continuous manufacturing processes, systems and plants for the production of high-value chemical products to higher quality, at lower cost and more sustainably.

By supporting a collaborative, multi-disciplinary programme the EPSRC Centre aims were to:

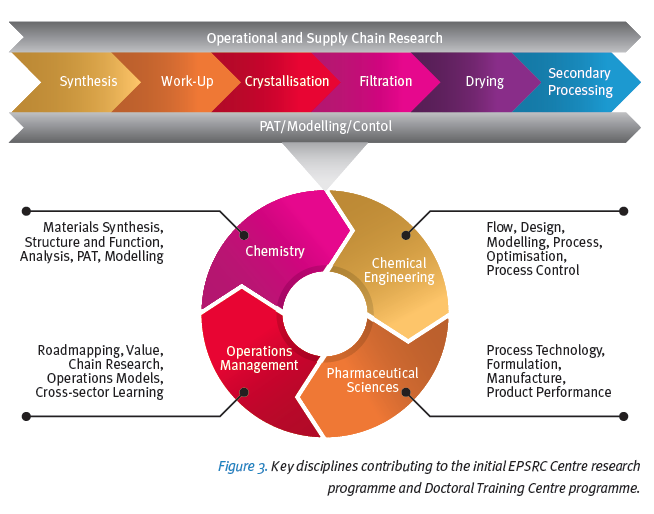

Key to the success of the Centre was the multidisciplinary academic team supporting the research programme. Our academic team included 14 academic investigators from 7 institutions working with PDRAs, PhDs, technical and administrative staff. The team harnessedexpertise in chemical and analytical, structural and materials chemistry, crystallisation science, pharmaceutical science, manufacturing and operations management, Figure 3. The academic team also contributed to the innovative training programme developed for the EPSRC Doctoral Training Centre in Continuous Manufacturing and Crystallisation that will train 45 doctoral researchers from 2012-2018.

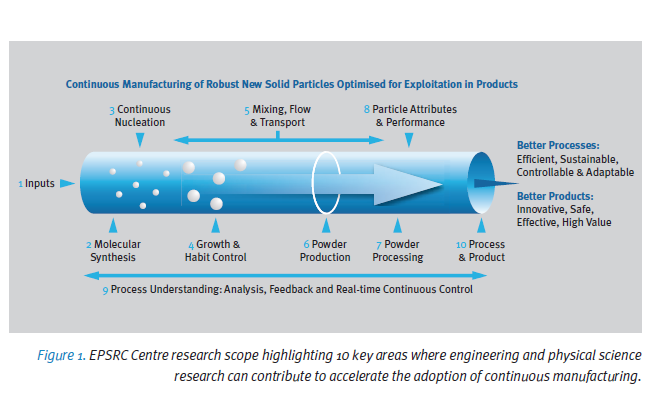

The research scope of the EPSRC Centre had been jointly defined by the academic team together with our industrial partners. The 10 key challenge areas were identified against the scope provide a focus for the academic engineering and physical science research activities.

Key Research Challenges were identified in collaboration with industry partners and the initial research programme defined. Further development of the research programme is an organic process and subject to regular reviews and modifications while maintaining a focus on the ten areas in the defined scope.

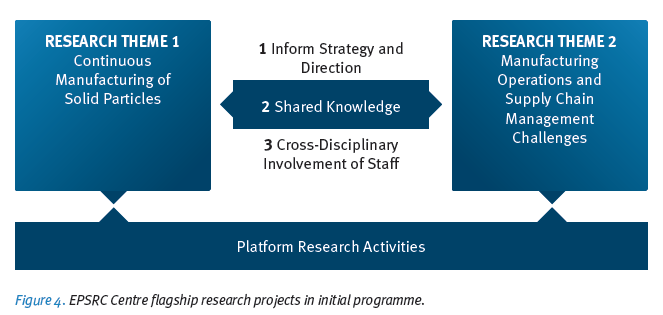

Our foundation research activity was delivered via our flagship research projects against key areas of the research scope (Figure 4). Along with the Centre’s core researchers a platform RA and technician were appointed to carry out short-term feasibility projects and assist in evaluation of new technologies.

The initial research programme (years 1-2) was split across two research themes and their corresponding work packages which worked together to deliver the collaborative multidisciplinary programmes of research.

Research Theme 1 - Continuous manufacturing of Solid Particles

Research Theme 2 - Manufacturing Operations and Supply Chain management Challenges in Continuous manufacturing of Solids

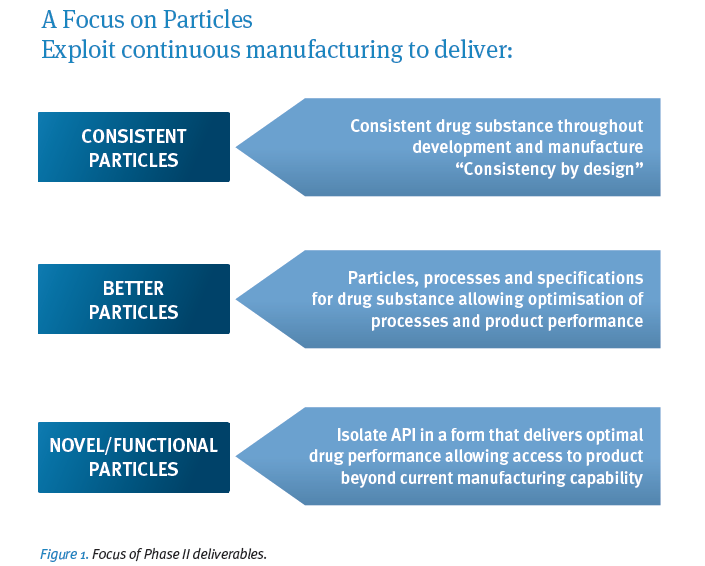

When the initial Centre flagship research programmes came to an end, Phase II (years 3-5) began. It focussed on integrating the research from across the centre from synthesis and work-up, through crystaliisation, secondary processing and to the final product and ensuring the supply chain is viable. This work was divided into three main workpackages. This builton the capabilities established and progress made in the initial flagship themes and delivered an ambitious co-ordinated programme of research to transform capabilities for continuous manufacturing of high value chemicals and in particular, pharmaceuticals. The direction of Phase II drew on the technical targets and industry problem statements collated by the Centre’s industry technical committee and on extensive discussions across the academic team. Whilst the emphasis of the programme remained in controlled continuous crystallisation, Phase II also built on downstream processing capabilities including continuous filtration, drying and secondary processing of API into formulated product. This included understanding how particle attributes impact on performance in downstream operations. Key enablers of Phase II were the new processing and analytical capabilities supported by the £34m UK RPIF award as well as new PhD and academic appointments. The Phase II research programme was delivered through three core work packages supported by the Phase II Centre funded RAs.

WP1 Laboratory-scale continuous process capabilities to support end-to end manufacturing WP2 Tools and workflows for rapid product assessment and continuous process selection WP3 Product-process archetypes that support supply chains of the future |

As part of the Phase II programme, research in the Centre started to actively target specific pharmaceutical products where there is a clear opportunity to develop new manufacturing technologies that can aid access to medicines in developing countries as well as addressing the healthcare needs of western economies. Projects began to target anti-malarials as well as treatments for HIV, type II diabetes and elevated cholesterol with outcomes demonstrating the ability to improve the medicines supply chain of the future.